NEETRAC specializes in both collaborative and proprietary research projects in a number of areas important to the industry. The results of these projects are used by electric utilities and manufacturers to improve the quality of transmission and distribution systems. We offer the services listed below and more!

High Voltage Testing

- HV / EHV Cable System Qualification

- RIV & Corona Testing

- Arrester Evaluation

- Insulator Evaluation

Environmental Testing

- Thermal Testing

- UV Testing (UVA & UVB)

- Salt Fog & Accelerated Laboratory Corrosion Testing

Mechanical Testing

- Structural Component Testing

- Condition Assessments

- Qualification Testing

- Analytical Services

Asset Management

- Diagnostics for Power Cables & Distribution Transformers

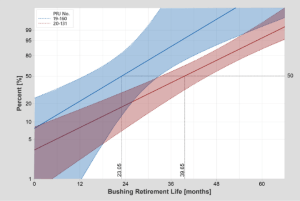

- Reliability / Survival Analysis

- Asset Management Strategies for Components and Energy Resources

- Population-Based Life Assessment

Grounding / Safety Practice Evaluations

- Ground Grid Integrity Tests

- Step and Touch Potentials

- Soil Resistivity Measurements

- Ground Grid Resistance Measurements

- WinIGS Simulation Studies

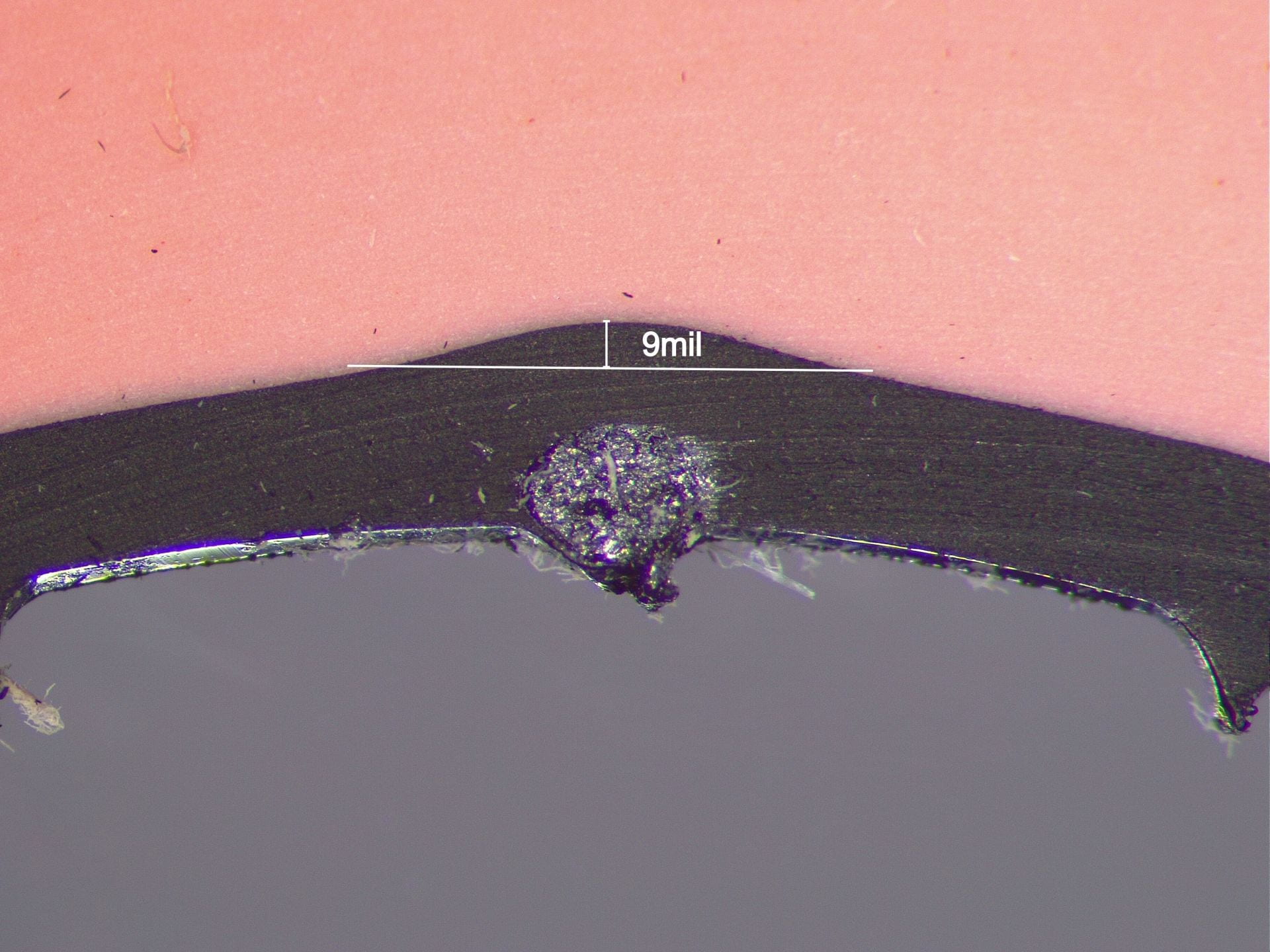

Failure Analysis

NEETRAC’s failure analysis capabilities include most components found between, and including, the generator bus bar and the customer power meter. Each failure analysis is unique, and a failure analysis team will be assembled to provide the necessary technical expertise. Whether it’s an underground cable, overhead connector, insulator, breaker, switch, lightning arrester, or another component, NEERAC’s engineers will work with you to determine the root cause of the failure.

Quality Assurance

NEETRAC has operated a cable QA program for over thirty companies, both Members and non-members over the last twenty-five years. The program, which identifies non-conformities and unusual features, covered orders representing 74 million feet of cable in 2021. These features are identified early enough for the purchasing utility to work with their supplier to prevent them from being installed on their system. The QA inspections requirements from IEEE C57.12.00, IEEE C57.12.28, and IEEE C57.12.31 include an inspection on the coating system, welds, labels, hardware for the enclosure, an insulation resistance test, and a transformer turns ratio test.